Industrial RO System Plant Manufacturer in Kolkata

Industrial RO System Plant Manufacturer in Kolkata

Industrial Reverse Osmosis System Plant Manufacturer in Kolkata

Industrial Reverse Osmosis System Plant in Kolkata

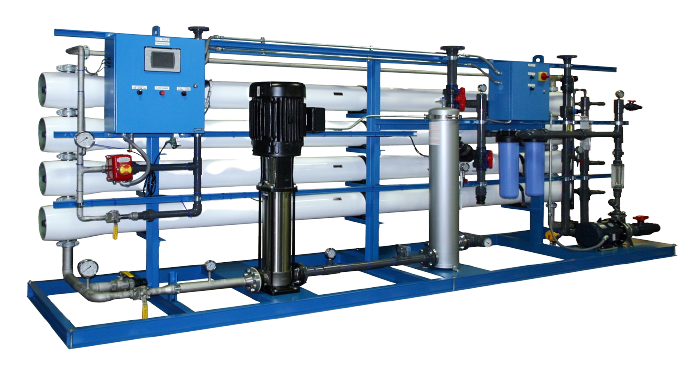

Industrial reverse osmosis is a highly effective industrial water treatment process that can reduce 97-99% of total dissolved solids (TDS) in water. Industrial reverse osmosis (RO) water systems are utilized in various processes such as food & beverage production, power generation, boiler feeds, oil & gas production, high-purity water generation, central sterilization, and manufacturing processes. The proper use of an industrial reverse osmosis system can protect production quality and downstream equipment.

An Industrial RO (Reverse Osmosis) system is a manufacturing plant which purifies contaminated water through the process of reverse osmosis. The Industrial RO Water plant requires a variety of pre-treatment methods such as softening, dechlorination as well as antiscalant treatment. After the pre-treatment process, a high level of pressure is used to send water through a semipermeable membrane which retains all the contaminants from the water and passes pure water through. Depending upon the concentration of salts and contaminants in the water, energy levels are determined.

On average, an industrial Reverse Osmosis plant needs 6 kilowatt-hours of electricity to purify 1 cubic metre of water..

What Else is Needed for an Industrial Reverse Osmosis System?

Industrial reverse osmosis systems can be packaged to be ready to use at your facility. However, industrial RO is not simply one piece of equipment. It is truly a reverse osmosis “system” that incorporates many different industrial RO components. While these components are in line with the RO, they precede the reverse osmosis unit, removing impurities that could quickly degrade the RO effectiveness or damage the RO unit. Adding these industrial reverse osmosis precursors can save money by reducing maintenance costs and downtime while extending the life of the industrial reverse osmosis system and the equipment that follows. Examples of equipment, chemicals, or other elements that may be important to include in your industrial reverse osmosis system include:

- Pumps

- Storage Tanks

- Pretreatment

- Carbon filters

- Sediment filters

- Water softeners

- Chemical feeds

- Anti-scalent

- Sodium Bi-sulfate / sodium metabisulfite

- Exchange DI tanks

- UV systems

- Filters (e.g. .2 Micron filters)

In addition, post-treatment of the industrial water that has been RO-treated may be desirable to create water that is uniquely suited for your downstream process. This may be particularly important for food & beverage and pharmaceutical manufacturing, but other environments will also benefit from post-RO treatment.

How Does Industrial Reverse Osmosis (RO) Work?

Industrial reverse osmosis (industrial RO) is a highly effective water treatment process for reducing up to 99% of dissolved mineral salts, organics, and other particles by forcing water under pressure through a semipermeable membrane. The process is named “reverse osmosis” because it is the opposite of the natural osmotic process, where water from a solution with a low concentration of dissolved solids travels through a membrane seeking to dilute a higher concentration solution. A reverse osmosis water system is induced by applying pressure with a pump to a solution with a high concentration of dissolved solids, causing water from the concentrated solution to pass through the membrane. This water is referred to as product water. Dissolved solids do not pass through the membrane; they are continually flushed to drain as waste. This flushing action also keeps the membrane surface from fouling or scaling.

Industrial RO System Plant Manufacturer in Kolkata

Why do we need an RO Water Plant?

RO system helps to purify the contaminated water which can be used for a variety of purposes such as:

- Drinking water

- Desalination

- Wastewater treatment

- Concentration of contaminants

- Reclamation of dissolved minerals, etc.

What are the advantages of an Industrial Ro Plant?

Industrial RO Plant is in high demand because of the following benefits it provides:

- It is easy to install and service.

- The process of reverse osmosis is reliable.

- It removes ionic salts, non-ionic, colloidal matter, viruses, active and inactive bacteria as well as high molecular weight organic matter.

- It is a fully automatic system.

- The water retrieved from the plant is safe to drink.

Types Of Industrial RO System

1. 100 LPH Industrial RO Plant

100 LPH RO Plant is suitable for small schools, hodpitals and institutes, small offices, hotels, etc. It is a heavy-duty system capable to operate for up to 10 hours and has a water recovery rate of 60%.

2. 150 LPH RO System

150 LPH RO plant filter 150 Liter impure water per hour. It is highly efficient and does not require general maintenance. It is energy-efficient and consumes less electricity.

3. 200 LPH RO Plant

200 LPH RO Ssytem suitable for meduim size building, complex, Schools etc. It cter the need of 400-500 people at once. It is easy to operate and maintain.

4. 250 LPH RO Plant

200 LPH RO system clean 250 liter contaminated water. It has low water Rejection Site.t is easy to operate with no manual work required.

5. 350 LPH RO Plant

Our 350 LPH RO Plant is suitable for hospitals, food processing units, hotels, etc. It is a heavy-duty system capable to operate non-stop for up to 10 hours and has a water recovery rate of 70%. I

6. Fully Automatic 500 LPH RO Plant

It can efficiently perform for the water requirement of 800 to 1000 people every day. It is trusted for its operational work and excellent capacity of 500 liters per hour with 6 filtration stages.

Industrial RO System Plant in Kolkata

| RO Capacity | 1000(Liter/hour) |

| Material | FRP |

| Plant Application | Industrial RO Plant, Institutional RO Plant |

| Design | Customized |

| Installation/Civil Work | Required |

| Operation Mode | Automatic, Manual, Semi-Automatic |

| Automatic Grade | Semi-Automatic, Automatic |

| RO Capacity (Liter/hour) | 1000-2000 (Liter/hour), >3000 |

| Types Of Machines | UV Sterilizer, Reverse Osmosis Unit, Activated Carbon Filter, Multi-Grade Filter |

| Material of Construction | SS Powder coating, FRP, Stainless Steel |

| Plant Accessories | Ozonator |

| Max Water Recovery Rate | >75 % |

| Number of Filtration Passes | >5 |

| Reverse Osmosis Systems Repair and Maintenance Required | No |

We have been able to establish ourselves as a reliable firm engaged in manufacturing Industrial Reverse Osmosis Systems.

Which Industries Use Industrial Reverse Osmosis (RO)?

Industries and facilities that typically use industrial reverse osmosis (RO) include:

- pharmaceuticals

- dairy

- semiconductors

- manufacturing

- factories

- power generation

- labs

- medical

- research

- food and beverage

- oil and gas

- correctional facilities

- universities

- hospitals

- hotels

There are numerous applications for industrial reverse osmosis systems beyond these mentioned.

Conclusion

Industrial RO Water Plant is an effective and latest technology manufacturing plant for purifying contaminated water that is suitable for many industrial purposes that require desalinated water. Proper monitoring and maintenance of the plant is important to prevent costly repairs and uncertain maintenance and provide many years of high purity water. If you are looking for an Industrial RO plant, contact an industrial plant manufacturer to know further details.

If You want to get the best manufacturer of Industrial RO System Plant in Kolkata and India , then Baba Pet Enterprise is the best option for you .. You can contact us .